Excavator shovel in robot hand

What is robotics and automation?

Robotics and automation are two closely interwoven technological fields that aim to make human tasks more efficient and precise. Robotics deals with the design, programming and control of robots - machines that perform complex tasks autonomously or partially autonomously. Robots are used in many sectors, for example in industry, medicine and agriculture, but also on construction sites. They can perform physical tasks such as assembling products, performing surgical procedures or cleaning floors.

Automation, on the other hand, generally refers to the use of technology to control and monitor processes with no or minimal human intervention. Both mechanical and digital systems can be involved. Examples of automation can be found in industrial production, where machines automatically assemble components, on construction sites, where materials are applied autonomously, or in IT, where software processes run automatically.

The aim of both disciplines is to increase efficiency, reduce errors and take over repetitive or dangerous tasks.

-

What opportunities are there for robotics and automation in the construction industry?

Robotics and automation offer numerous innovative possibilities in the construction industry. Automated construction machinery (e.g. excavators, dump trucks, wheel loaders) can carry out tasks such as earthmoving or concreting efficiently and precisely. In times of an ever-increasing shortage of skilled workers, well-trained employees can then concentrate on the necessary control and monitoring tasks.

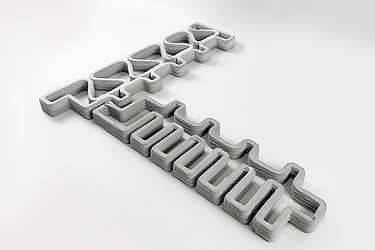

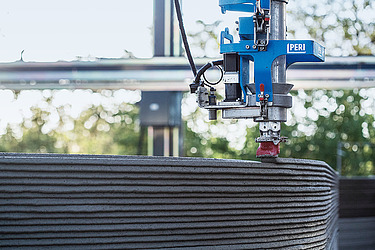

Bricklaying robots and 3D concrete printers enable buildings and structures to be erected quickly and accurately. Drones are used to survey construction sites and buildings and provide real-time data for project monitoring. Robots can also take over tasks in hazardous areas, for example at great heights or during demolition. In addition, digital automation optimizes work processes by making planning, logistics and administration more efficient.

The systematic integration of robotics and automation into ongoing processes is crucial for the successful use of robotics and automation on construction sites. This allows new standards to be created for large-scale use.Cobots (an abbreviation for "collaborative robot") are versatile, compact robots that act as supportive helpers on the construction site. They take on monotonous tasks such as gripping, screwing or drilling and actively adapt to different processes thanks to sensors and cameras. They are characterized by flexibility and precision, but at the same time are designed in such a way that safety systems, which perceive their environment via sensors, avoid injuring their human cooperation partners. -

What are the advantages of robotics and automation in the construction industry?

A major advantage of using robotics and automation is the increase in safety. By using robots, workers can be protected in dangerous areas, such as on high scaffolding or when working with heavy machinery. Robots take over high-risk activities and thus minimize accidents at work.

By relieving workers of heavy, repetitive tasks, they can concentrate on more creative and complex activities and maintain their health.Robotics and automation also offer great advantages in terms of precision. Automated systems work with millimeter precision and reduce errors. This leads to higher quality and reduces the need for rework, which also saves costs.All in all, it can be summarized as follows: Robotics and automation improve efficiency, safety and quality in the construction industry.

By relieving workers of heavy, repetitive tasks, they can concentrate on more creative and complex activities and maintain their health.Robotics and automation also offer great advantages in terms of precision. Automated systems work with millimeter precision and reduce errors. This leads to higher quality and reduces the need for rework, which also saves costs.All in all, it can be summarized as follows: Robotics and automation improve efficiency, safety and quality in the construction industry. -

What can we expect for the future?The future of robotics and automation promises ground-breaking developments in many areas. In industry, collaboration between humans and machines will continue to advance, with robots increasingly acting as intelligent partners that react flexibly to their environment and human colleagues. Such "collaborative robots" or cobots will become increasingly intuitive and safer in practical use.

With advances in artificial intelligence (AI) and machine learning, robots will be able to take on more complex tasks autonomously and learn continuously. In manufacturing, logistics and even healthcare, this could lead to a completely new form of efficiency, with robots making decisions and adapting to changing requirements.

The use of automation in agriculture, construction and care will also increase. Smart machines will take over routine tasks that previously only humans could perform.Autonomous vehicles and drones will also play a greater role, whether in transportation or infrastructure monitoring. Overall, these technologies will revolutionize the world of work by taking over repetitive, dangerous and precision-intensive tasks while creating new fields of work and opportunities.

How does STRABAG use robots and automation in construction?

As a leading technology group for construction services, STRABAG is already working with robots and automated systems on its construction sites. While some are still in test mode, others are already widely established.

The "robot dog" SPOT from the manufacturer Boston Dynamics can be found on many construction sites, where it moves independently according to a predefined route plan and takes care of construction site documentation.

STRABAG also has many years of experience in concrete printing with robotic systems. With the help of a giant concrete printer from PERI, Austria's first 3D-printed building was constructed in Hausleiten, Lower Austria. The printer produced a cavity wall from two parallel mortar sheets, which was then filled with in-situ concrete. The next step is the KARLOS mobile concrete printer from our technology partner Putzmeister, which produces complete, solid walls. A prototype of this was used in a project in Stuttgart.