Road raw material depot: How we recycle concrete roads

Resource-conserving renovation of the A2 southern motorway

The reuse of construction materials plays a key role in sustainable road construction - for example in asphalt recycling or the recycling of concrete roads. On the southern motorway in Austria, STRABAG is renovating an eleven-kilometre-long concrete carriageway and is not only recycling concrete and asphalt to a high degree, but also sand for the first time thanks to adapted regulations. The project shows how integrated construction material recycling works in practice and is promoted by partnership models.

What is a concrete road?

How does the recycling of the concrete road on the A2 motorway work?

To recycle the concrete road on the A2 motorway, the carriageway is first removed. This leaves concrete, asphalt and rock, which are transported to a mobile crushing plant not far from the construction site. The crushing plant crushes the material, which is then reused in the sub-base concrete and base courses. The material - 325,000 tonnes in total - is thus completely returned to the cycle. This is hardly ever done on this scale in Austria - and is therefore a real statement in favour of the circular economy in road construction! This saves around 13,500 lorry journeys, which not only reduces material consumption but also greatly minimises CO₂ emissions.

Recycling on the south motorway:

- Local material cycle: 325,000 tonnes of road demolition waste are processed and reused on site.

- Recycled asphalt: 40,000 tonnes of asphalt with a recycled content of 70 percent are used.

- More flexible regulations: Amended regulations mean that sand (aggregates 0 to 4 mm) can be recycled for the first time.

New rules, more recycling

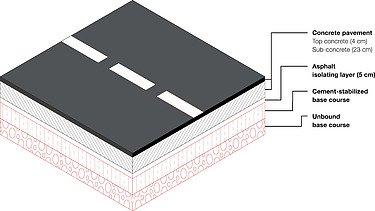

We are also increasing recycling in other areas: in the asphalt layer that is applied between the cement-stabilised base layer and the concrete layer above - also known as the clean layer - we use asphalt with a recycled content of 70 percent. This is almost four times higher than is usual on Austrian motorways. As a rule, the proportion here is 20 per cent.

What role do partnership models play in sustainable road rehabilitation?

Factsheet:

A2 Road renovation