Our streets clean the air.

With Clean Air Asphalt – ClAir® Asphalt for short – STRABAG is helping to make roads more sustainable. The multifunctional asphalt surface layer from STRABAG AG simultaneously purifies the air and reduces noise, thereby minimising the impact of vehicle traffic on people and the environment. ClAir® Asphalt uses the process of photocatalysis to reduce the concentration of toxic nitrogen oxides such as nitrogen dioxide (NO2) in the air. An added benefit is that the special texture of the asphalt surface significantly lowers the rolling noise from tyres interacting with the road.

STRABAG’s TPA competence centre developed the innovative asphalt together with nine partners from science and industry as part of the NaHiTAs (Sustainable HighTech Asphalt) research project funded by the German government. Following the Neckartor pilot section in Stuttgart, STRABAG AG and TPA Germany have now implemented numerous road construction projects with ClAir® Asphalt wearing courses.

Simple idea, enormous impact: reducing pollution through photocatalysis

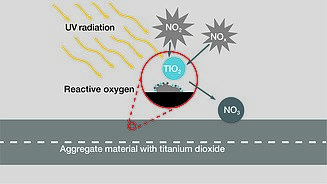

ClAir® Asphalt achieves its pollutant-reducing function through the use of titanium dioxide (TiO2). Titanium dioxide is a naturally occurring material, obtained as a powder, with a photocatalytic function that is used by the asphalt to help protect the environment.

Through the UV component of normal sunlight, titanium dioxide acts as a catalyst to convert the nitrogen oxides (NOx) bound in the air into harmless nitrates.

Simple idea, big impact: fighting pollution with photocatalysis

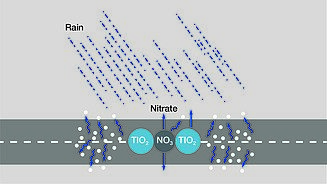

ClAir® Asphalt achieves its pollutant-reducing function through the use of titanium dioxide (TiO2). Titanium dioxide is a naturally occurring material, obtained as a powder, with a photocatalytic function that is used by the asphalt to help protect the environment. Through the UV component of normal sunlight, titanium dioxide acts as a catalyst to convert the nitrogen oxides (NOx) bound in the air into harmless nitrates.

Installation with STRABAG’s innovation paver

For the asphalt surface course, ClAir® Asphalt uses an aggregate made of crushed ultra-high-performance concrete (UHPC) mixed with small amounts of titanium dioxide. Since the titanium dioxide only acts through direct contact with UV radiation, the pollutant-reducing material must be present directly at the road surface. For this purpose, the STRABAG competence centre TPA has developed an innovative new type of paver that can sustainably incorporate the photocatalytic aggregate into the still hot road surface directly during the asphalt paving process.

Fewer pollutants and less noise

ClAir® Asphalt makes use of photocatalysis to reduce the nitrogen dioxide concentration in the air by up to 26 % under good conditions – lots of sun and little wind. The photocatalyst TiO2 is not used up but remains in the road surface and maintains its functionality. At the same time, ClAir® Asphalt reduces traffic noise levels at reference speeds of 40 km/h to 50 km/h by 2 dB(A) to 4 dB(A). In terms of acoustic perception, this corresponds to a reduction in the traffic volume of up to 50 %.

Factsheet:

ClAir® Asphalt