Resource-saving road renovation on the A1

Asphalt recycling project on the Westautobahn in Austria

How does sustainable road rehabilitation work on the A1?

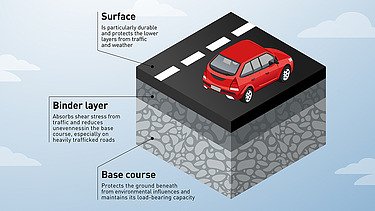

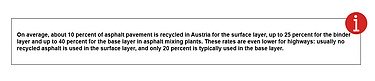

More environmentally friendly road rehabilitation can be achieved through higher recycling rates in the asphalt mix. In some projects, it is already possible to use an above-average amount of recycled material with the consent of the client.

A higher proportion of used asphalt saves important resources in road rehabilitation. The asphalt mix used on the A1 comes from our advanced asphalt mixing plant in Hausleiten. It is one of the most modern in Austria. In purely technical terms, it could produce asphalt mix from 100 percent used asphalt.

More asphalt mixing plants of this kind are needed in Austria in order to produce mixes with a particularly high recycling rate throughout the country in the future.

How do we guarantee quality in our asphalt recycling projects?

Recycling reduces the need for stone and bitumen. The asphalt recycling project on the A1 shows two things. 2Firstly, the reuse of asphalt can conserve important resources and save CO emissions. Secondly, recycling reduces the cost of purchasing raw materials. Bitumen in particular is a fossil raw material that should be avoided in the interests of environmental protection. It is also expensive and chemical processing to make hardened bitumen liquid again is significantly cheaper.

On the A1, STRABAG was able to carry out the contract for ASFINAG at a lower price while maintaining the same quality. The tests on the mix with 40 percent recycled content were carried out by the TPA (Gesellschaft für Qualitätssicherung und Innovation) team in their laboratory in Trumau. This enables us to ensure the quality of the highway.

In purely qualitative terms, even higher rates of road rehabilitation would be possible. However, there is a lack of important empirical data, for example on the question of how asphalt quality develops over the years of road use. Asphalt pavements with recycled content are generally subject to strict quality controls, which are carried out on a close-meshed basis and for a longer period of time after paving. For example, the skid resistance of the pavement and the strength of the layers are tested. In the event of defects such as cracks in the asphalt or rutting, the construction company must repair or even replace entire layers.

How can road renovations in Austria become even more sustainable?

The STRABAG team used around 94,000 tons of recycled material on the A1 out of a total of 114,000 tons of asphalt mix. Of this, 24,800 tons are pure old asphalt. The asphalt recycling project shows that STRABAG can carry out road renovations with used asphalt of the same quality as usual. One approach to increasing the use of used asphalt would be to use it more in the base course. This is because it does not have to meet the same requirements as the surface course. For our colleagues on the construction site, using recycled materials makes no difference.

Everyone must pull together to achieve this: The clients, the planners, the construction companies and the politicians. We need strong partnerships, such as with ASFINAG, to further promote asphalt recycling and make road renovations more sustainable.

Factsheet:

A1 Sustainable road renovation