Recycling and research, circular economy business park

Our contribution to achieving the climate targets and reducing carbon emissions in Bremen

As a small federal state, Bremen has to import all the materials needed for construction – in part from the surrounding area, although hard rock also has to be brought in from Scandinavia or Scotland. Materials accumulated during demolition are downcycled at best and usually just dumped in a landfill, which requires them to be transported over hundreds of kilometres away. If Bremen wants to achieve its climate targets, urgent action is needed to decentralise and streamline the city’s supply chains.

At the same time, the 13-hectare site of a former refinery tank farm on the north side of the harbour, heavily contaminated with oil, has been lying unused for almost 20 years. In 2022, STRABAG Environmental Technology bought this property with the aim of reclaiming the site in order to build and operate a state-of-the-art technology and competence centre for urban mining and construction waste processing. A symbolic groundbreaking ceremony for the STRABAG Circular Construction & Technology Center (C3) in Bremen also marked the start of the remediation works.

Remediation: resource-efficient and sustainable

A prerequisite for construction at the site is its remediation and the creation of a uniform ground level with a useful area of approx. 86,500 m². The remediation concept is based on a complete relocation and sealing of the existing soil stockpiles on site. At the same time, the site is cleared of explosive ordnance and measurements to determine the concentration of hazardous substances in the soil are carried out. The soil is then excavated and separated according to its mechanical properties before being further processed, if necessary. In this way, the contaminated grounds on the entire site are being successively secured. By relocating the stockpiles on site, we cut down on the need for transport that would otherwise be needed, thereby eliminating the carbon emissions associated with the use of heavy goods vehicles.

The remediation process also allows us to obtain recycled building materials that we use later to construct the surfaces of the base course, for example. The only waste that is removed and discarded is waste that cannot remain on the site because it is harmful to groundwater and to the environment.

Climate-neutral construction and energy-autonomous usage concept

In the construction of the recycling plant, we pay attention to climate-friendly construction methods and use mainly wood and recycled concrete as building materials. The usage concept is environmentally friendly and cutting-edge as well: Following completion, the site will be energy self-sufficient and climate neutral. The electricity requirement is largely covered by the home's own photovoltaic system; electricity storage units help to cover any peak loads. A heat pump provides environmentally friendly heating energy. A rainwater collection system allows the construction waste processing and the sanitary facilities to be operated with rainwater. Green roofs with retention chambers for water storage serve as biohabitats. Landscaping is also planned along the embankments as further ecologically valuable space.

Technology and research

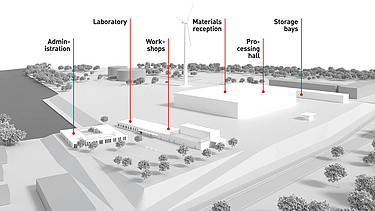

The site will be used by our environmental technology units, who will develop the location into a technology and research campus. Our goal is a lofty one: to sort and process demolition material down to the finest grain sizes in order to recover almost 100 % of the raw materials. The aim is not to process the construction waste to yield a low-quality alternative to reclaimed landfill materials. Instead, we want to recycle the demolition material and concrete to achieve a level of quality that eliminates the need for new raw materials in the first place. In other words: a high-tech circular economy.

In addition to creating around 130 workplaces for our employees, we are also planning a start-up campus with co-working spaces for research into construction waste recycling. The aim is to work together with universities, colleges, testing laboratories and institutes that have a close connection to urban mining and the bio-economy. Together with our partners, we want to find new materials that have previously not been recycled. Sand, for example, can currently not be reused. In the long term, this work and research platform is to become a centre of excellence – and an example of what tomorrow’s circular economy will look like.

With its lighthouse project in Bremen, STRABAG is an Exhibition partner of the German Pavilion Expo 2025 Osaka Consortium.

At the German Award for Sustainability Projects 2023, the STRABAG Circular Construction & Technology Center (C3) in Bremen has been named the winner in the Raw Materials and Procurement category.

Factsheet:

C3 Bremen