Sustainable Construction: Low-Carbon Concrete

Why do we build with concrete?

For buildings, roads, tunnels, bridges, dams or skyscrapers – concrete is an indispensable part of construction. But let’s not fool ourselves: concrete doesn’t have the best carbon footprint. And yet, it will continue to play an important role in construction in the future – because few other building materials have such good structural properties. This is why the continuous decarbonisation of concrete construction is a key element of our sustainability strategy. We are systematically working on technologies to reduce concrete’s carbon footprint, and together with partners from industry and research, we are gaining important experience in the use of low-carbon concretes. To help us accomplish even more in this area in the future, we need one thing above all: clients who are willing to work with us on progress.

Why does concrete generate such high levels of carbon emissions?

Standard concrete contains cement as a binding agent. And the production of cement alone is responsible for about 6-7 % of the world’s greenhouse gas emissions. That is four times as much as all of the global air traffic combined.1 That’s because the production of cement involves the use of cement clinker, made from limestone, sand and clay, which is burned at high temperatures involving a high energy consumption. Most of the carbon emissions are caused by the chemical reaction that takes place in the process, as the deacidification of the limestone produces unavoidable, resource-related greenhouse gas emissions.

What can STRABAG do to help reduce concrete-related carbon emissions?

We are systematically working on technologies to reduce concrete’s carbon footprint, are implementing research and pilot projects on low-carbon concrete and are entering into new partnerships with concrete manufacturers and clients. To help us accomplish even more in this area in the future, we need one thing above all: clients who are willing to work on progress with us during their projects.

What is low-carbon concrete? And how do you reduce the carbon in concrete in the first place?

Low-carbon concretes are concretes that have a lower Global Warming Potential (GWP)3 compared to standard concretes. About 80 % of the greenhouse gas emissions of common standard concretes come from the Portland cement clinker used in its production. The key to reducing emissions here is therefore to lower the percentage of clinker used.4 Our in-house building materials technology competence centre – TPA Gesellschaft für Qualitätssicherung und Innovation – is working on three alternatives to reduce or replace the cement clinker content in concrete:

- Reducing the cement content of concrete

- Using low-clinker cement

- Using alternative binders with a low Global Warming Potential

Use of low-carbon concrete: a real-world example

The construction of our new Innovation Center corporate offices in Stuttgart marked the first time that we exclusively used low-carbon concrete for all cast-in-place concrete components and temporary construction elements. The STRABAG and ZÜBLIN team used 9,151 m³ of the CEM III/B low-clinker, blast-furnace cement, gathering extensive experience and knowledge in building with low-carbon concrete.

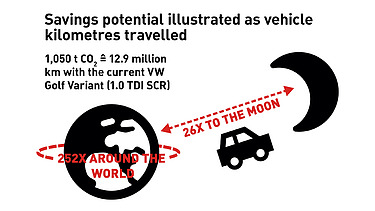

The result: The use of ready-mixed, low-carbon concrete allowed us to cut carbon emissions by 1,050 tonnes during the construction of the Innovation Center compared to the average values from the ÖKOBAUDAT platform.5 This corresponds to savings of over 50 % during the structural works.

The experiences gained from the Innovation Center project show:

- The use of low-carbon concrete can cut carbon dioxide emissions by between 30 % and 50 %, depending on the basis of comparison used. Further savings potential is possible by combining the use of low-carbon concrete with other changes, for example during planning and in the choice of construction method.

- Low-carbon concrete can be used without additional testing or approval – in contrast to cement-free concretes, for example, whose use without further testing is still prohibited by current building standards.

- There are no constraints in the installation and processing of the concrete and no drawbacks with regard to the quality of exposed concrete sections in the Innovation Center project.

It should be noted that:

- Delayed early strength development of low-carbon concrete poses a number of challenges for building construction operations.

- The use and availability of low-carbon concrete needs to be assessed on a project-by-project basis.

Focus on alternative materials

STRABAG is working on research into concretes with cement-free binders. We are also investigating the use of materials that can permanently store greenhouse gases from the atmosphere, while at the same time reducing the amount of cement in the concrete, thus lowering the environmental footprint already in the product. STRABAG screens the market for such suitable technologies, evaluates their potential and supports our teams in their use in practice.

1 Source: VDZ, Ed.: Decarbonising Cement and Concrete: A CO2 Roadmap for the German Cement Industry. Düsseldorf, 2021. Available at: https://vdz.info/dekarbonisierung, Executive Summary in English

2 Greenhouse gas emissions (GHG) in German industry in 2017. Source: Own illustration based on figures from the Competence Centre on Climate Change Mitigation in Energy-Intensive Industries (KEI), emission data from the German Environment Agency (UBA), Wuppertal Institute, and the VDZ and WV Stahl associations (2017). Available at: https://www.klimaschutz-industrie.de/themen/zementindustrie/

3 The global warming potential is the potential contribution of a substance to warming the atmospheric layers close to the ground, i.e., the contribution to the greenhouse effect. This contribution is stated as a GWP value relative to the greenhouse potential of carbon dioxide (CO2).

4 Source: InformationsZentrum Beton GmbH: Umwelt Produktdeklaration – Beton der Druckfestigkeitsklasse C25/30 [Environmental Product Declaration – Concrete of Strength Class C25/30], Erkrath, 2018; InformationsZentrum Beton GmbH: Umwelt Produktdeklaration – Beton der Druckfestigkeitsklasse C45/55 [Environmental Product Declaration – Concrete of Strength Class C45/55], Erkrath, 2018. Both available at: https://ibu-epd.com/en/published-epds/

5 The CO2 emission avoidance figure of 1,050 tonnes was obtained by taking the following parameters into account: The GWP values for the lean concrete types (corresponding to C8/10 and C12/15) were provided by the concrete supplier; the GWP values of all other types of concrete correspond to the EPDs (Environmental Product Declaration) from the ÖKOBAUDAT reference year 2018 for concrete of the compressive strength classes C30/37 and C50/60 as unreinforced structural concrete according to DIN EN 206-1; the installed concrete types contain small amounts of accelerator admixtures, which, due to their effects, were not shown separately; the installed reinforcing steel is not covered by this analysis; any influencing factors from the construction process, such as higher formwork costs (additional transports, etc.) do not form part of this CO2 analysis.

Factsheet

Low carbon concrete