Building with wood: climate-friendly and energy-efficient

Using wood as a building material has a tradition that goes back thousands of years. Wood is not only one of the oldest building materials known to mankind, it is also a key building material for the future if we want to make the transition to a sustainable construction industry. As a biotic renewable resource that grows back after use, and as a natural CO2 reservoir, wood has a much better carbon footprint than other building materials. Further advantages of wood include several important technical and logistical advantages in addition to its universal applicability and long service life.

For STRABAG, the increased use of wood in construction is an important building block on our way to becoming climate neutral across the entire value chain by 2040. To reach this goal, we are drawing on the know-how and the years of experience of our experts at ZÜBLIN Timber and Obermayr Group, who have established themselves in leading roles in the market for timber and timber-hybrid buildings. It is a growing market, and the number of clients who insist on building with wood has been steadily increasing for years. In Germany, for example, more than one in every five residential and non-residential buildings is now predominantly built with wood.

What makes building with wood sustainable?

As a renewable and natural resource, wood can be obtained and processed into a building material with relatively low levels of energy consumption and CO2 emissions. So wood can serve as a substitute for other building materials that have an energy-intensive production associated with high levels of CO2 emissions.

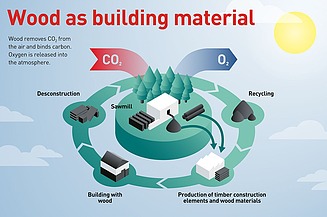

Building elements made of wood are also natural CO2 reservoirs. This is because trees extract climate-damaging CO2 from the atmosphere for use in photosynthesis. In the process, oxygen (O2) is released into the atmosphere, and carbon (C) is bound in the wood. The CO2 is only returned to this cycle when the wood rots or is burned. If, on the other hand, the wood from the trees is used for construction, the CO2 remains stored there in the form of carbon. As a rule of thumb, one cubic meter of wood binds about one ton of CO2.

Wood can be easily recovered during demolition or dismantling works and recycled with very little energy used. It can also be disposed of in a much more environmentally friendly manner than other building materials such as concrete or steel.

These advantages make wood the ideal building material to lead the way into a low-carbon building industry in the future. The origin of the wood, however, is a crucial factor in determining whether it can truly fulfil its potential as a sustainable building material. The timber used in construction should exclusively be sourced locally from sustainably managed forests (certified forestry). Long transport routes to the processing plant and/or the construction site must be avoided.

Policymakers are also hoping that using wood as a building material will help them to achieve their climate targets. With its timber construction initiative, the German federal government aims, among other things, to create targeted incentives for “climate-friendly construction with wood” as it leads the way as a “pioneer in climate- and resource-efficient construction”.

What other properties does wood have as a building material?

- Wood has a relatively low thermal conductivity. That makes timber construction an ideal solution for energy-efficient buildings. The heating energy requirement is lower in wooden buildings and/or the walls don’t need to be as thick as in concrete buildings, which reduces the amount of material used.

- With a relatively low weight (lighter than concrete, steel or bricks), wood has high tensile and compressive strength and an excellent load-bearing capacity, capable of supporting 14 times its own weight. The high stability and resilience of wood makes it possible to build relatively thin, material-saving structures in timber or timber hybrid construction projects.

- Building elements made of wood, such as ceilings, walls, beams or façade components, are usually industrially prefabricated. At the construction site, they merely have to be assembled or installed and – unlike concrete – do not need to dry, which greatly reduces the overall construction time. Construction projects with a high proportion of wood can be completed more quickly, largely independently of the weather, and at a lower cost. This makes wood the perfect building material for serial and modular construction projects using highly standardised, prefabricated parts. ZÜBLIN Timber, for example, adds insulation and façade (LENO®-ADD) to wall elements made of cross-laminated timber already ex works and combines wood and concrete in its modular timber-hybrid construction system MOLENO.

- Another advantage of timber construction is that, as a natural product, wood ensures a pleasant and cosy atmosphere and creates a naturally regulated indoor climate. Wood not only stores heat over a longer period of time but also absorbs moisture from the room air and releases it again when it is dry.

- Because wood is weather-dependent, absorbs moisture and reflects sound, building with wood requires careful planning to counteract any potential disadvantages of timber construction before the project gets started. Modern timber structures ensure an airtight building envelope and sufficient structural protection against moisture as well as good noise and thermal insulation.

- Wood is combustible. But it burns only very slowly and in a controlled manner as a protective char layer forms in the event of a fire. This means that the load-bearing capacity of timber buildings is maintained for a relatively long time in case of fire and the fire remains predictable. Because of its combustibility, wood is also subject to strict fire protection regulations that must be met in order to obtain a building permit.

Where is wood used as a building material?

Wood can be used universally in almost any building in almost any way. As a building material, there are practically no design limits: solid wood or glulam elements are used as columns and beams, cross-laminated timber modules form walls and ceilings, façades can be built from wood, as can floors and terraces or doors and window frames. Construction timber must be dry and durable. Common types of wood that are used as a building material are domestic softwoods such as spruce, fir, larch, pine or Douglas fir.