Sustainable soil utilization

Conserving resources through earth recycling

The six-lane widening of the A 8 motorway near Pforzheim is removing one of the last bottlenecks between Karlsruhe and Munich. STRABAG and ZÜBLIN are jointly widening the 4.8 km section to three lanes in each direction. A large difference in height of around 100 metres has to be overcome for the section of road through a deep depression in the Enztal. This requires 1.1 million cubic metres of soil to be moved - a huge amount that will be almost completely recycled.

What is excavated earth?

Excavated earth or excavated soil is the term used to describe earth that is produced during the construction of excavation pits for building projects. Large quantities of excavated soil are produced, particularly when developing residential areas and in road and mining construction. As this excavated material is not construction waste, it must be disposed of separately. The A 8 Enztalquerung motorway crossing project does not involve disposal, but instead relies on soil recycling. By treating resources with respect, we not only avoid high disposal costs and thousands of truck journeys, but also save 8,943 tons of CO2e.

Soil recycling - an environmentally friendly alternative to disposal

Excavated soil mainly consists of naturally grown earth material such as humus in the topsoil as well as rock, clay, sand and gravel. These materials are generally uncontaminated, contain no pollutants and can be recycled for construction work without restriction after thorough sieving out of larger stones. Only the humus-rich topsoil is unsuitable for this purpose, as it is not load-bearing due to its high organic content and rots quickly. The excavated material for the A 8 project consists mainly of sand, gravel, crushed stone and clay in the upper layers and high-quality shell limestone in the deeper regions.

Not all excavated earth is the same

Soil utilisation is subject to conditions that must be observed. If the soil is interspersed with natural residues such as roots or branches, but also waste, it is considered contaminated. If the soil is inseparably contaminated by heavy metals or toxic substances such as acids and alkalis, it is considered polluted and can only be reused to a limited extent after a microbiological decontamination wash. The excavated soil from the A8 project is analysed for contamination in a laboratory and measured to ensure that only uncontaminated materials are reused within the construction site and the water protection zones. The majority of the excavated material does not require any additional processing and can be used directly as soil material in earthworks on the construction site.

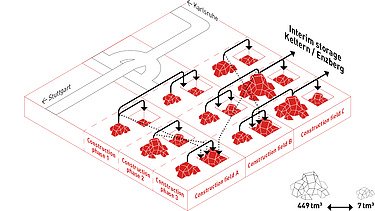

Sustainable soil recycling: 90 % reused

Even before construction began, STRABAG and ZÜBLIN were thinking about soil recycling together with their client, the south-west branch of Autobahn GmbH. The project team recorded every material flow in detail in a comprehensive concept: Where is the excavated material generated and where can it be sensibly reused? This forward-looking planning has made it possible to reduce disposal to a minimum. The result: around 90% of the excavated earth is reused directly on the construction site.

DGNB pre-certificate "Sustainable construction site"

As industry-wide pioneers, STRABAG and ZÜBLIN are systematically establishing sustainable processes on their construction sites in Germany. STRABAG AG was the first company in the nationwide transport infrastructure construction sector to be awarded the "Sustainable Construction Site" basic certificate by the German Sustainable Building Council (DGNB). This certificate applies to the entire company and creates the basis for the certification of individual projects. For final certification of the construction sites, evidence must be provided on an ongoing basis, which is regularly checked by the DGNB until the projects are completed.

Selected measures for more sustainability on the A 8 Enztal crossing construction site:

- Noise protection: Noise-intensive chiseling work can be avoided by means of underground blasting.

- Dust avoidance: Dust emissions can be reduced by using prefabricated parts.

- Soil and groundwater protection: An environmentally friendly refueling concept is implemented. Rainwater is collected and cleaned in clarifiers before being discharged into the River Enz.

- Sustainability & resource conservation: Extensive earth recycling concept saves primary raw materials

Factsheet:

A8 Enztal crossing