Sustainable robot ballet on the construction site

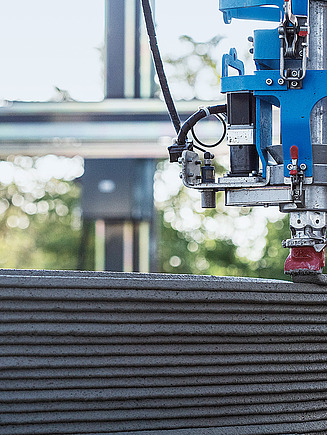

Individually mobile robots are capable of printing lightweight walls directly on the construction site, revolutionising conventional construction processes in a sort of synchronised dance.

The 3DLight_OnSite research project has a clear and important goal: to advance the use of 3D concrete printing in construction and to make the technology more flexible. One way of achieving this flexibility is through the use of mobile construction site printers, i.e. 3D printing robots that are individually mobile but closely synchronised with each other so they can jointly print wall elements directly on the construction site. This would make construction projects more flexible and also more sustainable, thanks to the use of new materials and the special lightweight construction method that is employed in 3D concrete printing.

3DLight_OnSite: taking 3D concrete printing one step further

The project unites three key topics in its name: 3D concrete printing for lightweight construction directly on the construction site. Through these three essential factors, we are driving the evolution of concrete printing. Why? Because we see great potential here to do things better. 3DLight_OnSite combines several trends that are crucial for the industry: concrete printing, construction robotics and, of course, sustainability. As the project encompasses so many different topics, interdisciplinary work is extremely important. For this reason, we are working closely together with other companies, universities and research institutes to achieve the best possible results.

Digitalisation, sustainability and more efficiency

We want to make the most of the economic and environmental potential of 3D printing. This first requires a consistently digitalised construction process: from the compilation of the building data in a BIM model (Building Information Modelling) to the transfer of that data to the printing robots. Seamless data transfer creates more efficiency on the construction site.

At the same time, we are increasing our focus on sustainability. The robots use more environmentally friendly types of concrete than is usual in conventional concrete construction, and they can print the concrete using an extremely material-efficient lightweight method of construction inspired by the honeycomb structure of bees. Less material means lower costs and at the same time a smaller carbon footprint: a win-win situation for economy and the environment!

Using these levers, we can optimise the building processes of the future and offer a glimpse of tomorrow’s sustainable construction industry already today.

Factsheet:

3DLight_OnSite